Fabrication Work

Metal Fabrication is the creation of metal structures by cutting, bending, assembling process .our large fabrication floor can handle many value added process from concept to design to final products.

Our Fabrication Floor is Well Equipped with advanced Laser Cutting Machine, CNC Bending Machine, Lathe & Drilling Machine & All types of Welding Machine Such as Electrical, ARC, Argon, Gas Welding with Different size of grinding & painting equipments.

Argon Welding

The ASME code requires that welders are certified to specific weld procedures used to fabricate the ASME code vessel. Welder certifications must be documented and maintained. A weld map must be generated that shows which welder performed each weld on an ASME code vessel.

MS & SS Fabrication Jobs

Here’s one more difference between heavy metal fabrication and light. In light fab the work is generally taken to the process while in heavy fab the process – especially welding – comes to the work.

To elaborate, heavy metal fabrication generally entails constructing large, and therefore heavy, structures. These aren’t easily moved through the fabrication shop: that takes cranes and fork trucks and causes a lot of disruption. So instead, cutting, welding, grinding and painting gear is brought to the job, which itself creates a few challenges.

When you talk about needing strength, as for the aforementioned heavy fabrications, you’re talking about steel and sometimes stainless steel. Not in sheet form but as I-beams, pipe and tube and of course plate. Now plate is one area where a formal definition does exist, ASTM standards.

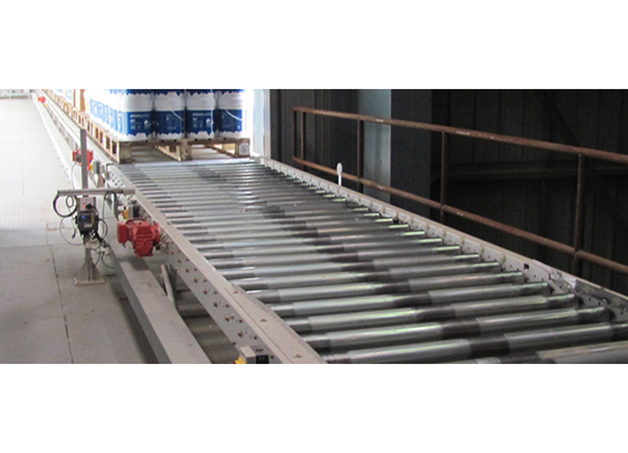

Conveyor System

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. ... There are chain conveyors (floor and overhead) as well.

Material Handling Solutions

Good material handling functions are: (a) To speed up the movement of equipment, assist with mechanical aids, and eliminate manual labour. (b) Reduce the transport involved in the production of a material.

We help medium size manufacturing on the handling and storage of incoming materials, packaging and shipping methods, production planning, as well as workforce scheduling. Industrial Engineers design, develop, test, and evaluate integrated systems for managing processes.

Grease Trap

A grease trap is a plumbing device (a type of trap) designed to intercept most greases and solids before they enter a wastewater disposal system.

o put it simply, a grease trap is a receptacle into which wastewater containing FOG flows through before entering a drainage system. The receptacle is designed to intercept or "trap" the FOG while allowing clear water to escape.

.jpg)